Clear coat is a vital component in collision repair, enhancing vehicle aesthetics by seamlessly blending panels while offering structural protection against corrosion, moisture, chips, and scratches. Its application process involves advanced techniques, tools, and precise parameters to achieve flawless results, highlighting the skill of auto body technicians. Starting with dent removal, cleaning, and thin, even coats, clear coat securely bonds to paint, ensuring panel junctions are virtually invisible, thus maintaining vehicle longevity and aesthetic appeal through professional body shop services.

In the realm of automotive repair, achieving seamless blending panels is paramount for a collision-free finish. Clear coat plays a pivotal role in this process, serving as the final protective layer that fuses colors and textures smoothly. This article delves into the science behind clear coat’s transformative abilities, exploring its function, benefits, and best practices for application. By understanding these key aspects, professionals can master the art of seamless blending, ensuring collision-free panels that rival factory-fresh appearances.

- Understanding Clear Coat: Its Function and Benefits in Panel Blending

- The Science Behind Clear Coat's Seamless Blending Effect

- Best Practices for Applying Clear Coat to Achieve Collision-Free Panels

Understanding Clear Coat: Its Function and Benefits in Panel Blending

Clear coat plays a pivotal role in seamlessly blending panels during collision repair, offering more than just aesthetic appeal. This protective layer serves as the final touch in auto body services, enhancing the overall quality of vehicle restoration. Its primary function is to create a smooth, uniform surface by filling in imperfections and concealing seams, making it nearly impossible to distinguish where one panel meets another. This meticulous process ensures that every blended panel looks like it was originally manufactured as such, contributing to both visual perfection and structural integrity.

The benefits of clear coat in panel blending extend far beyond mere appearance. By sealing the joint, it prevents corrosion and moisture penetration, which are common issues in auto body restoration. Moreover, clear coats provide a durable finish that resists chips, scratches, and fading, ensuring the restored vehicle retains its glossy, pristine condition over time. This meticulous attention to detail not only enhances the car’s exterior but also attests to the skill and precision of the auto body technicians involved in the collision repair process.

The Science Behind Clear Coat's Seamless Blending Effect

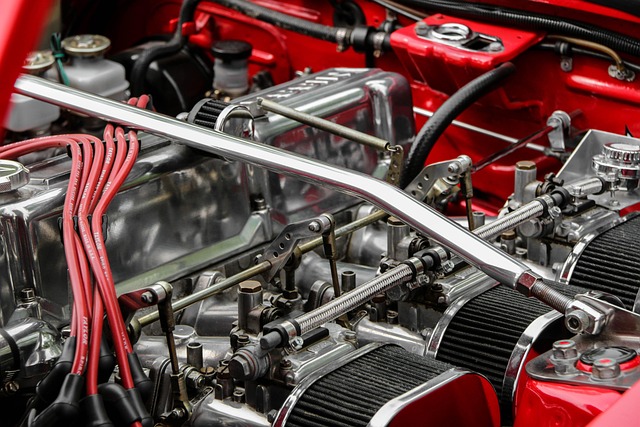

The science behind clear coat’s seamless blending effect lies in its unique composition and application process. Clear coat, a thin, glossy top layer, is designed to protect the underlying car bodywork while providing an impeccable finish. During application, the clear coat molecules adhere tightly to each other and to the panel surface, creating a smooth, seamless blend where panels meet. This is particularly crucial when dealing with collision repair, ensuring that the repaired area matches the original car bodywork perfectly.

The key to achieving this lies in the precision of the application process. Skilled technicians use specialized tools and techniques to apply the clear coat evenly, filling any gaps or imperfections left by the collision. The result is a virtually invisible joint, enhancing the overall aesthetics and value of the vehicle repair services provided. This seamless blending not only restores the car’s exterior beauty but also ensures long-lasting protection against future damage.

Best Practices for Applying Clear Coat to Achieve Collision-Free Panels

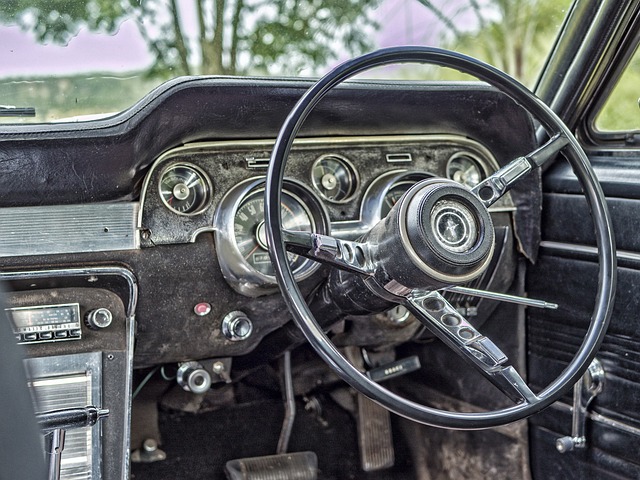

To achieve seamless blending panels with a clear coat, best practices involve careful preparation and precise application. First, ensure the surface is free from any dents or imperfections using advanced dent removal techniques commonly offered by professional body shop services. This step is crucial as even minor defects can disrupt the final finish. After smoothing, thoroughly clean and degrease the panel to create a clean canvas for the clear coat.

During application, use a thin, even layer, focusing on areas where panels meet. Employ an efficient spraying technique, maintaining consistent pressure and distance from the surface. Allow adequate drying time between coats as recommended by the manufacturer. This meticulous approach ensures the clear coat bonds securely with the underlying paint, creating a collision-free blend that enhances vehicle aesthetics and longevity, thereby underscoring the value of professional body shop services in achieving flawless results.

Clear coat plays a pivotal role in seamlessly blending panels, eliminating visible joints and enhancing the overall aesthetics of automotive repairs. By understanding its function, the science behind its effectiveness, and adopting best practices for application, professionals can achieve collision-free panels that rival factory finishes. This ensures higher customer satisfaction and maintains the vehicle’s value.