Blending panels in collision centers enhances repair efficiency and quality. This technique combines damaged parts to match original designs, reduce labor costs, and minimize structural weaknesses. Standardized methods ensure consistent results for various vehicles, maintaining aesthetic integrity. For cost-effective solutions, especially in Mercedes-Benz repairs, blending panels from donor vehicles offers genuine parts at lower costs while streamlining rare part acquisition for classic cars.

In the realm of professional collision repair, panel blending is a game-changer. This efficient technique, involving the precise merging of damaged car panels with new or repaired ones, streamlines work processes and ensures consistent quality. By adopting panel blending, collision centers achieve remarkable results in both repair speed and final product, all while offering cost-effective solutions. This article explores why this standardized practice is essential for high-quality, economical repairs.

- Efficient Repair: Blending Panels Streamlines Collision Work

- Quality Assurance: Standardized Blending for Consistent Results

- Cost Savings: Why Panel Blending Is Economical for Professionals

Efficient Repair: Blending Panels Streamlines Collision Work

In collision centers, efficient repair processes are paramount to ensuring quick turnaround times and satisfied customers. Blending panels is a technique that streamlines collision work significantly. By blending different sections of a damaged panel together, technicians can create a seamless patch that matches the original vehicle’s design, both aesthetically and structurally. This method eliminates the need for multiple, smaller repairs, reducing labor costs and potential weaknesses in the final fix.

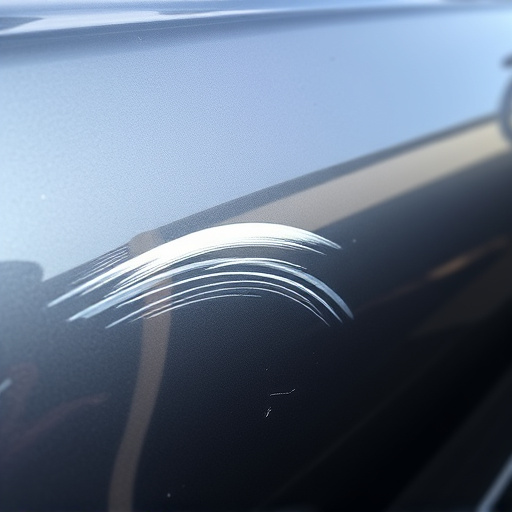

Moreover, blending panels enhances precision during fender repair, bumper repair, or any other cosmetic restoration work. It allows for precise matching of colors and textures, ensuring that the repaired area is virtually indistinguishable from the rest of the vehicle. This level of craftsmanship not only boosts customer satisfaction but also helps collision centers maintain their professional reputation.

Quality Assurance: Standardized Blending for Consistent Results

In the realm of collision repair centers, offering superior auto body services is non-negotiable. Panel blending, a meticulous process, plays a pivotal role in achieving flawless outcomes. When it comes to quality assurance, standardized blending techniques are the cornerstone for consistent results across diverse projects, from modern car models to classic car restoration endeavors. By adopting uniform blending methods, collision repair centers can ensure every panel replacement or repair seamlessly merges with the existing vehicle surfaces, eliminating visible seams and imperfections.

This standardization is particularly beneficial in maintaining aesthetic integrity throughout the entire process. Whether dealing with a complex bodywork overhaul or a simple dent removal, consistent blending ensures that the final product appears as though it was never damaged. For collision repair centers aiming to provide top-tier auto body services, mastering panel blending techniques is indispensable.

Cost Savings: Why Panel Blending Is Economical for Professionals

Panel blending is a cost-effective solution for professional collision centers, offering significant savings compared to traditional methods. By utilizing a diverse range of donor vehicles, or “blending panels,” technicians can access a broader selection of genuine parts at a fraction of the cost. This practice is especially beneficial in the intricate world of Mercedes-Benz collision repair, where original equipment manufacturer (OEM) parts can be pricey. With blending panels, repair shops can still maintain high-quality standards while reducing expenses for both themselves and their clients.

Imagine a scenario where a fender or a door panel from a newer model vehicle is needed for a classic car repair. Blending panels allows collision centers to bypass the challenge of sourcing rare parts, as they can often find suitable alternatives from other vehicles within their inventory. This not only saves time but also ensures that even intricate scratch repairs or fender repairs on beloved classics are both feasible and economical.

Panel blending is a game-changer in the collision industry, offering efficient repair processes, quality assurance, and significant cost savings. By standardizing blending techniques, professional collision centers can achieve consistent, high-quality results, ensuring customer satisfaction and streamlined operations. This innovative approach to auto body repairs positions blending panels as an indispensable tool for any modern collision shop looking to stay ahead in the market.